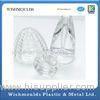

CNC Rapid Prototype Electronic Plastic Parts Enclosures For Music Equipment

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Sound Equipments Louder Speaker Cover Electric Plastic Parts Plastic Moulding

Sound Equipments Louder Speaker Cover Electric Plastic Parts Plastic Moulding

Wishmoulds Service

1. Equipmented with high precision CNC, EDM, Wire-cutting, Grinder, Lathe, Milling, injection machines from 50T to 800T, wishmoulds can supply you with both Mold & Molded parts

2. Provide CNC Prototypes, Mold Design, Mold Making, Mold Testing, injection molded parts, Products assembly, packing, shipping, etc services.

3. With about 20 years experience in mold making and molded parts, Wishmoulds can provide you the perfect solutions quickly.

4. Low volumes / Small orders/ high volume production are acceptable.

5. Accept only OEM / ODM / Customer Projects.

All the plastic products we make are customized by our customers

6. Mold building lead time: Around 25~30 days, with 1st Mold trialing report and Mold trailing samples

Description:

1. When you’re ready to set up your tooling and manufacturing, DH has professional experience to get it done right, you’ll get good lead times along with the quite competitive quality and integrated project management.

2. Plastic injection molding is used to produce thin-walled plastic parts for a wide variety of applications, DH Mold has built its reputation for reliability by consistently providing precision tooling and high quality molded parts for a variety of industries including

1). sports equipment; 2) Piano key; 3) automotive parts; 4). medical equipment; 5) industrial components; 6) consumer products; 7).home appliances 8).aerospace area; 9)household product

3. Our capabilities and expertise include Rapid Prototyping, injection moulding, stamping moulding, die casting, packaging, and assembly among others. we are ability to post process and surface finish like printing(silk screen ) ,painting, plating, polish, ultrasonic-welding as one stop service .

| Wishmoulds Electric Plastic Parts Description | |||||||

| Design software | UG, ProE, Auto CAD, Solidworks, etc. | ||||||

| Mold Type | Plastic Injection Mould | ||||||

| Certificate | ISO 9001:2008 | ||||||

| Plastic production Raw material |

PP,Pa6,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR, silicone rubber,etc (flame retardant, UV as optional) |

||||||

| molded parts size | As per your drawing or samples | ||||||

| Color | According to your Panton number color or your samples | ||||||

| parts finish | Polish, Texture, Painting, chrome, silk sreen, etc. | ||||||

| Molded Parts features | Free of flash, sink mark, blemishes, variation, etc. | ||||||

| Parts application | Automative, Industrial, Household applicance, Vehicle, Medical, Food processing, Agriculturaletc. |

||||||

| lead time | 1 week | ||||||

| Packing | bulk or individual pack, upon customer's demands with exported carton box. | ||||||

Mold Making & Molded Parts Procedure

1. OEM projects ( enquiry)

2. Quotation ( Based on 3D drawing or samples provided by clients)

3. PI & Payment

4. Wishmoulds mold design

5. Wishmoulds mold making

6. Wishmoulds Mold testing and send samples

7.Customer confirm the samples

8. Mass production

Related Search

Find more related products in following catalogs on Hisupplier.com

Company Info

WISHMOULDS Plastic & Metal Ltd. [China (Mainland)]

Business Type:Manufacturer

City: Dongguan

Province/State: Guangdong

Country/Region: China (Mainland)

You May Like:

Sitemap XML

About HiSupplier Help Center Customer Service Friend Links Site Map Archives

Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory

Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español