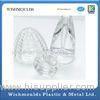

3D Design Plastic Engineering Products USB Shell Plastic Injection Molding Services

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

3D Design USB Shell Plastic Engineering Products Plasstic Molding

<span style=

3D Design USB Shell Plastic Engineering Products Plasstic Molding

Mould & Molded Parts Description

| Wishmoulds Mold Description | |

| Mold Type | Plastic injection mold, overmolding, Interchangeable Mold, insert molding, compression mold, etc |

| Design software | UG, ProE, Auto CAD, Solidworks, etc. |

| Main services | Prototypes, Mold design, Mold making, Mold tesing, low volume/high volume plastic production, Packing, Assembly. |

| Certificate | ISO 9001:2008 |

| Steel material | 718H,P20,NAK80,S316H,SKD61, etc. |

| Plastic production Raw material | PP,NYLON,PLA,AS,ABS,PE,PC,POM,PVC, PET,PS,TPE/TPR etc |

| Mold base | HASCO ,DME ,LKM,standard |

| Mold runner | Cold runner, hot runner |

| Mold hot runner | DME, HASCO, YUDO,etc |

| Mold cold runner | point way, side way, follow way, direct gate way,etc. |

| Mold strandard parts | DME, HASCO, etc. |

| mold life | >300,000 shots |

| Mold hot treatment | quencher, nitridation, tempering,etc. |

| Mold cooling system | water cooling or Beryllium bronze cooling, etc. |

| Mold surface | EDM, texture, high gloss polishing |

| Hardness of the steel | 30~60 HRC |

| Equipments | High speed CNC, standard CNC, EDM, Wire cutting, Grinder, Lathe, Milling machine, plastic injection machine |

| Lead time | 25~30 days |

| Month Production | 50 sets/month |

| Mold Packing | standard exporting Wooden case |

General description

1. We custom the plastic products according to your concept, design or samples.

2. Material: ABS, PP, PVC, PC, PS, PMMA, NYLON, POM, TPE, EVA, etc.

3. Working Process: injection molding, overmoulding.

4. Mould Base Material: LKM, HASCO, DME, or as customer's requirement.

5. Surface Treatment: polishing, texture,chrome plating,etc.

6. Usage: All kinds of cars, machinery, home appliance, electronic products, electric appliance, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more.

Process Steps

a. Quote competitive price according to customer detail requirement

b. Sign agreement

c. Customer T/T deposit to us for starting to design mould

d. Sent mould drawing to customer for confirmation

e. Mould design confirmed and start to make mould

f. Make mould trial during tooling time(which we get agreement with customer)

g. Send mould trial sample to sustomer for inspection. Or customer come to our factory to inspect mould personally

h. Customer T/T blance to us after mould confirmed

i. Delivery mould after get balance

| Wishmoulds injection molded parts Description | |||||||

| Design software | UG, ProE, Auto CAD, Solidworks, etc. | ||||||

| Certificate | ISO 9001:2008 | ||||||

Related Search

Plastic Injection Molding Machine

Plastic Injection Molding

Injection Plastic Molding

Custom Plastic Injection Molding

Injection Plastic Molding Machinery

Plastic Injection Molding Machinery

More>>

Find more related products in following catalogs on Hisupplier.com

Company InfoWISHMOULDS Plastic & Metal Ltd. [China (Mainland)]

Business Type:Manufacturer You May Like:

Printable Page

Bookmark this page

Sitemap XML About HiSupplier Help Center Customer Service Friend Links Site Map Archives Browse by: China Suppliers - Hot Products - Products Directory - Offers Directory - Suppliers Directory - Buyers Directory Language Option: العربية - Nederlands- Français- Deutsch- Italiano- 日本語- 한국의- Português- Pусский- Español Copyright © HiSupplier.com Online Inc. All Rights Reserved.

| |||||||